(1) Properties:

- Model: GOODRICH 76378

- Net weight of hoist: 98.6lbs

- Total capacity of cable: 600lbs=267 daN

- Total length of cable: 94m (usable length: 90m)

- Shear capacity of cable: 1,500 daN

- Working voltage: 28VDC

(2) Performance and limits:

- Lifting speed from 0 to 0.75 m/s

- Lifting angle: ± 20°

- The motor switches to low speed (1/3 of full speed) automatically for the last 2m of travel of cable. The speed limit is off only after the cable travels downwards more than 2m.

- The cable stops when it travels downwards to the red paint section.

- The end of cable’s downward travel is painted red./li>

Range of limits

- Ambient temperature: -45 ºC ~ 54 ºC

- Continuous hoisting: 6 upward travels with full load +6 downward travels with half load and 1 downward travel with full load (2 continuous hosting operations shall be separated by a 45-minute rest) (76378-060).

- Number of hoisting: unlimited; stop when the red indicator lights up on the control box (76378-260).

(3) Hoist assembly:

- Hoist body

- Hoist control joystick

- Hoist control box

- Steel cable

- Fixing ring

Hoist control box: (the box controls safety and protection settings)

- Automatic speed regulation

- Warning system

- Safety shutoff

- Logic circuit

Fixing ring specs

-

4 in the cabin

-

2 on the hoist

-

Working capacity: 2,500daN

-

Working capacity of cabin floor buckle: 1,500kg

(4) Cause of hoist overheating:

- The cable is easily overheated as it travels downwards in low speed.

- It takes more power out of the motor to rotate the pulley upwards; the pulley is easily overheated when rotating downwards.

- The greater the load, the more easily to overheat

- An indicator will flash when the hoist is overheating.

- Stop‧Turn power off‧Wait until it is cooled off

- No temperature limit for cable

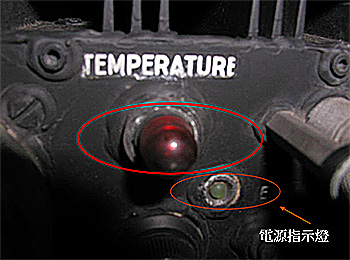

(5) Warning indicators:

- 150 ºC ≦ Temp < 175 ºC : the red indicator flashes

- 175 ºC = Temp : the red indicator flashes

- 175 ºC > Temp : the hoist stops; the power has to be turned off for a period of time to allow the hoist to cool off before turning the power on to resume hoisting.

(6) Other faults:

- Green indicator OFF (hoist not working)

A. Faulty connection to power supply

B. Blown fuse

C. Wiring damage

D. Faulty circuit in the control box

- Green indicator OFF (but hoist is working) blown bulb

Hoist overheating warning indicator and power indicator

(7) Temperature limit warning indicator:

- Red indicator on

A. Motor temperature circuit activated

B. Motor temperature circuit open

C. Connection circuit damaged

D. Control box damaged

- Red indicator flashing

A. Motor overheated

(8) Cable structure:

- Every cable is made by twisting 19 strands of 7 wires together.

- The cable is made of nickel steel but can still be rusted.

- The inner strands are more vulnerable since they are subject directly to tension and pulling.

- The strands is 4.5~4.8mm and wires 0.30mm~0.35mmin diameter

(9) Notes for exterior check of cable:

-

(10) Cable head structure:

-